With the popularity and promotion of new energy vehicles today, we can see electric vehicles everywhere when we walk on the street. I believe that many of you will be curious about how to charge electric vehicles safely. This article introduces several mainstream EV charging methods.

The existing EV charging methods are roughly divided into two types: slow charging and fast charging.

Slow Charging

Slow charging is a kind of AC charging, through the vehicle charger on the electric vehicle to convert the 120V AC power into 300-400V high voltage DC power, and then through the distribution box to charge the battery.

At present, the power of mainstream vehicle chargers on the market is mainly around 3.5kw and 7kw, and the charging current is mostly below 20A, so it takes 8-10h to charge this charging method the biggest drawback fully.

The slow charging method is more suitable for home use because of the low installation cost of charging posts. Slow charging is also very beneficial for extending the battery’s life because the current power battery used in electric vehicles is primarily lithium-ion batteries.

The higher the charging rate, the greater the risk of lithium precipitation for lithium batteries. After the negative electrode precipitation of lithium, it will bring the battery capacity decay (expressed as a decline in range) and bring the risk of thermal runaway caused by lithium dendrites piercing the diaphragm.

So for our ordinary electric car users, time permitting, the typical slow charge charging is perfect for the battery.

Fast Charging

Fast charging is a kind of DC charging which connects to an external fast charging pile through a DC charging interface and charges the battery after a high voltage distribution box.

The power of this fast charging pile is generally between 30kw and 150kw, which can charge the battery to 80% SoC in about 30 minutes.

At present, the industry’s fast charging method is mostly high-current charging because in constant power conditions, to enhance the charging speed, either high voltage or high current. Still, there is a significant safety risk of high voltage, so it is primarily high-current charging.

Because of the fast charging speed, it is trendy among users. However, this charging method requires high cell design and process requirements and requires battery manufacturers to have muscular strength in chemical body matching and charging strategy optimization.

At the same time, fast-charging piles have a high investment cost, large electricity consumption in the short term, and an enormous impact on the power grid, requiring a series of supporting infrastructure.

But it is undeniable that the development of a new generation of efficient super-fast charging piles and long-life power battery technology is crucial to the development of the entire new energy vehicle industry because the improvement of charging speed can significantly enhance the user experience, improve the efficiency of the user’s car and reduce waiting time.

So in the future, safe and efficient fast charging technology will be the focus of battery manufacturers and charging pile manufacturers.

EV Power Battery Fast Charging

A good fast EV charging strategy should improve the battery’s charging speed, improve the battery’s cycle life, and, more importantly, ensure safety.

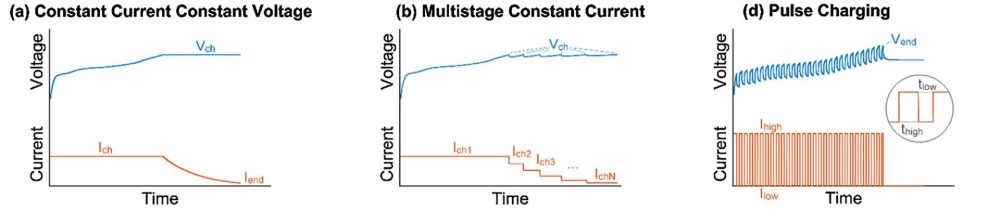

The current fast EV charging methods can be roughly divided into the following three: constant current constant voltage (CCCV), multistage constant current (MSCC), and pulse charging (PC).The current fast charging strategy used for electric vehicles is mostly MSCC.

The schematics of these three methods are shown below.

Constant Current Constant Voltage (CCCV)

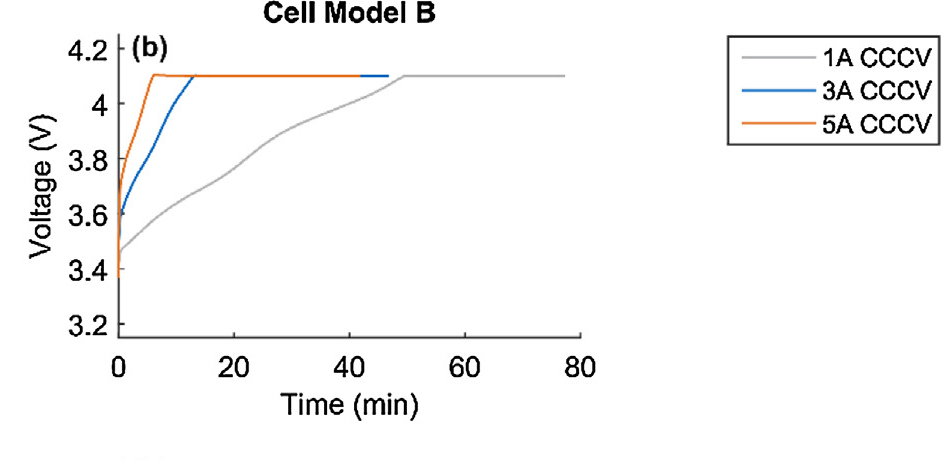

CCCV charges the battery to the cut-off voltage with a constant current and then to the cut-off current with a constant voltage afterwards.

If the fast charging time is fixed, then charge the battery with a higher current all the time. However, if the current is higher, it causes an increase in the polarization of the battery so that the battery reaches the cut-off voltage very quickly. However, the battery is not fully charged and can only be depolarized by a slow constant voltage to continue charging.

This charging method will result in a long charging process and is not very suitable for application to the actual fast charging strategy of the whole vehicle.

However, the CCCV method also has its advantages. This charging method is relatively fixed, which facilitates the unification of standards and is used more by cell companies to evaluate battery performance in the R&D stage and host manufacturers to verify and evaluate battery performance.

Multistage Constant Current (MSCC)

MSCC uses a step-like current to charge the battery, with the end of each step corresponding to a cut-off voltage. This approach makes more rational use of the battery’s capacity.

The specific principle is as follows. A battery with a specific chemistry system has a fixed fast-charging interval. As the charging SoC increases, the charging capacity of the cell decreases.

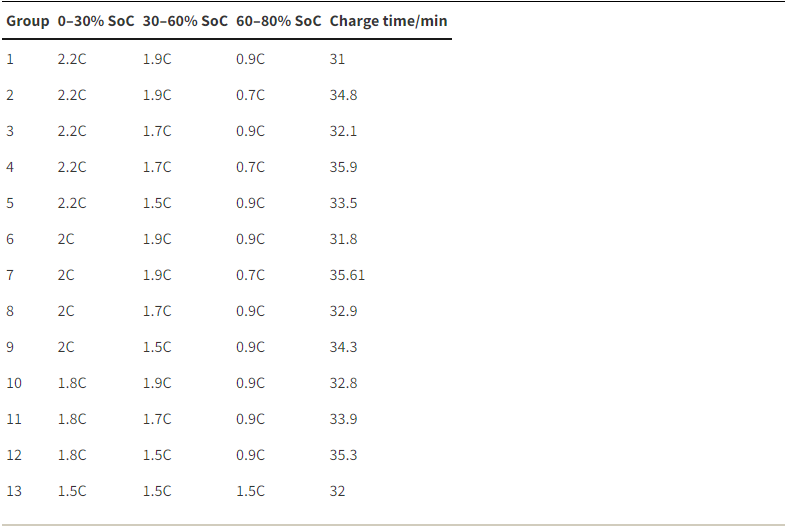

MSCC allows flexible adjustment of the charging multiplier. The battery’s charging capacity is high in the low SoC range, and increasing the charging multiplier can increase the charging speed.

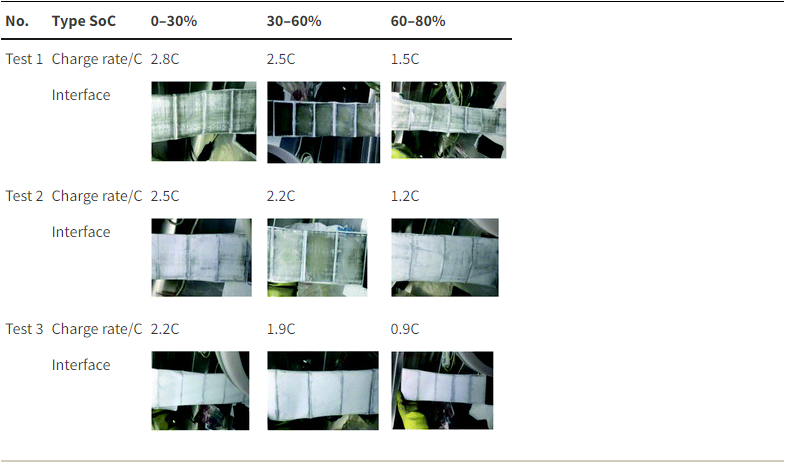

While in the high SoC range, the battery’s charging capacity becomes weaker and decreasing the charging multiplier ensures that the battery does not precipitate lithium throughout the charging process.

By finding the maximum charging capacity without lithium precipitation in different SoC zones, combined with the total fast charging time requirement, we can obtain a series of fast charging strategies.

Then by verifying the battery cycling performance through actual charging and discharging experiments, we can get the best charging strategy.

Therefore, compared with CCCV, MSCC electricity is more beneficial to improve battery life.

Pulse Charging (PC)

PC applies an instantaneous high current to charge the battery, after which the current drops to 0 and is left to stand for a short period, then an instantaneous discharge is applied. The battery is charged quickly by alternating the process of instantaneous high current charging – resting – instantaneous high current discharging.

The concentration difference polarization generated by rapid high rate charging is reduced by instantaneous resting and discharging. The problem of low charging capacity due to the rapid arrival of the battery at the charging cut-off voltage is avoided.

Currently, PC is not as widely used in EV charging as MSCC because the instantaneous current required for PC charging requires a higher grid load. In addition, charging posts using PC technology must have a discharge point function while charging the battery. These are still not small challenges for the technology at this stage.