Wire, in the automation industry and even the electrician industry are very important materials, generally made of copper or aluminum. Wire connection is the basic skills that electricians need to master, but also a very important work. At the same time, we also need to consider the safety aspects of electricians, then the quality of the wire connection is directly related to the entire line can be safe and reliable long-term operation.

The common wire connection

In the electrician’s work in accordance with the structure of the commonly used wire single-stranded wire and multi-stranded wire, this article will start from the two commonly used wire to introduce in detail.

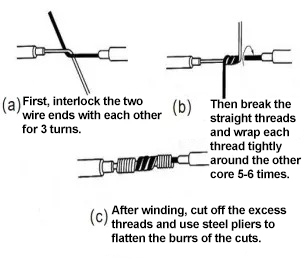

(1) Small cross-section single-stranded copper wire connection method

Specific steps as shown in the figure, the first two wires of the core wire head for the “X” shape cross, and then wrap them around each other 2 to 3 laps after wrenching the two threads straight, and then each thread in the other core wire tightly close to the dense winding of 5 to 6 laps after cutting off the excess threads can be.

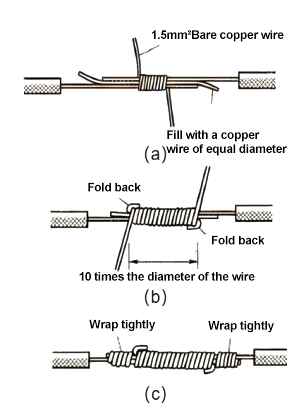

(2) Large cross-section single-stranded copper conductor connection method

The specific steps are shown in the figure.

(a) First in the overlap of the core wire of the two wires into a core wire of the same diameter, and then use a cross-section of about 1.5mm ² of bare copper wire in its tight winding.

(b) Then fold back each of the core wire ends of the connected wires.

(c) And then both ends of the winding bare copper wire continue to wind 5 to 6 turns after cutting off the excess wire.

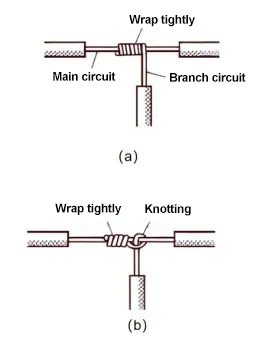

(3) Branch connection of single stranded copper wire

The operation steps are shown in the figure.

(a) The tip of the branch core wire is tightly wrapped around the trunk core wire for 5 to 8 turns and then the excess tip is cut off.

(b) For smaller cross-section of the core wire, the branch core wire can first be tied in the trunk core wire of the thread a wrap-around knot, and then tightly wound 5 to 8 turns after cutting off the excess thread can be.

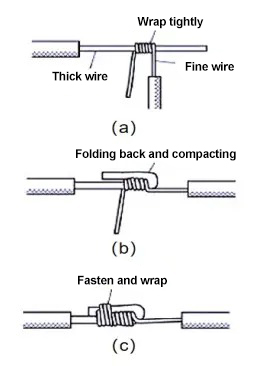

(4) Unequal diameter single-stranded copper conductor connection

The operating procedure is shown in the figure.

(a) First, tightly wind the core wire of the thin conductor on the core wire of the thick conductor for 5 to 6 turns.

(b) The thick wire core wire of the wire folded back tightly pressed in the winding layer.

(c) And then use the fine wire core wire in its continued winding 3 to 4 turns after cutting off the excess wire can be.

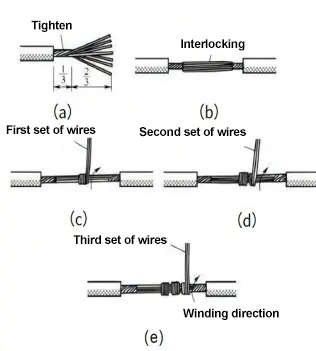

(5) Direct connection of multi-stranded copper wires

The operation steps are shown in the figure.

(a) First of all, strip the insulation layer of the multi-stranded core wire straight, will be close to the insulation layer of about 1 / 3 core wire stranded tight, and then the remaining 2 / 3 core wire into an umbrella-like spread, another need to be connected to the conductor core wire is also so dealt with.

(b) Pinch the core wires flat after inserting the two umbrella-shaped core wires into each other opposite to each other

(c) Then each side of the core wire thread into 3 groups, first of all, a side of the first group of thread warped and tightly wound on the core wire

(d) Then the second group of threads is cocked and tightly wound on the core threads.

(e) Finally, warp and tightly wind the 3rd set of wires around the core wire. Wrap the other side of the wire in the same way.

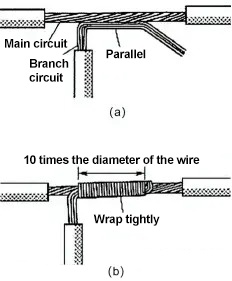

(6) Branch connection of multi-stranded copper wires

The specific operation steps are shown in the figure.

(a) Bend the branch core wire at 90 degrees and then parallel it with the trunk core wire.

(b) will be folded back and tightly wound on the core wire can be.

The point of connection of the wire specification

1. Planing and cutting wire insulation, should not damage the core.

2. The wire intermediate connection and branch connection should be used welding, wire clips, porcelain joints or crimping method of connection

3. Branch line connection, the trunk line should not be from the branch line of the lateral tension.

4. Cross-section of 10 square and below single-stranded copper wire, 2.5 square and below multi-stranded copper wire and single-stranded aluminum wire and electrical appliances can be directly connected to the terminals, but the multi-stranded copper wire should be tightened to hang the tin before connecting.

5. Multi-stranded aluminum core wire and cross-section of more than 2.5 square multi-stranded copper core wire terminals, should be welded or crimped terminals, and then connected to the terminals of the appliance.

6. Wire if welding, the residual flux and slag of the terminal should be removed. Solder should be filled to the brim and acidic flux should not be used.

7. The joints should be wrapped evenly and tightly with insulating tape, not less than the insulation strength of the original wire.

8. It is strictly prohibited to exploit or connect the wire with electricity.

Related Products