Like traditional fuel vehicles, new energy electric vehicles are equipped with a small 12V or 24V battery. It is mainly used to provide electricity to the vehicle’s lighting system, audio system, instrumentation system and so on. Because of the small capacity of the small battery, it needs to be charged frequently.

We all know that traditional fuel cars will drive the generator to charge the small battery through the transmission belt when the engine is running. But there is no traditional engine and generator in new energy electric vehicles.

So what components does it use to charge the small battery?

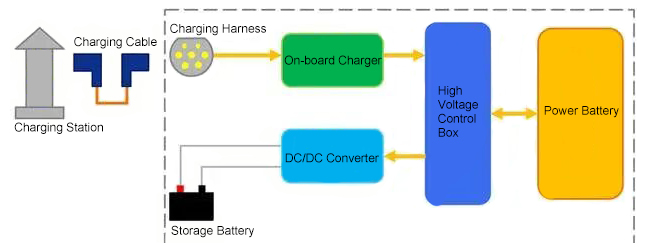

In order to solve the problem of how to charge small batteries in new energy electric vehicles, engineers have installed an on-board DC/DC converter in the vehicle. It is the core component for charging small batteries and powering the lighting system, instrumentation system, audio and media system, etc. in new energy electric vehicles. The specific function is to convert the direct current (DC) from the high-voltage power pack into 12V or 24V low-voltage direct current (DC) for use by the vehicle’s low-voltage power equipment and for charging small batteries.

Because the on-board DC/DC converter needs to be fixed installed in the car. In order to reduce the weight of the vehicle and ensure the safety and stability of the vehicle in the process of operation. So it needs to have a small size, light weight, cold and heat resistance, anti-vibration, anti-drop and waterproof, good heat dissipation, high conversion efficiency, long service life, stable and reliable, safe and energy-saving and so on.

New Energy Vehicle DC-DC Converter Status Quo

Now the new energy on-board DC-DC converter adopts the international advanced full digital control technology, LLC resonant frequency modulation technology, constant current and constant voltage automatic conversion technology, etc. It has the core advantages of small size, light weight, large power passenger, high conversion efficiency, waterproof grade IP67, long service life, stable and reliable work, shockproof and drop-proof, high safety, etc., and it is widely used in the world’s major vehicle manufacturing.

When the new energy electric vehicle starts, the on-board DC/DC will convert the high-voltage DC of the power battery into low-voltage DC for the use of low-voltage power equipment. If you find that your car can not be started, the horn does not sound, the lights do not come on, then it is very likely that the on-board DC/DC converter is faulty.

On-board DC/DC converter internal generally consists of a control chip, inductor coil, diode, transistor, capacitor and so on. Its working principle is that the high-voltage power battery through the high-voltage distribution box to the high-voltage DC power delivery to the DC/DC. And then by its output 12V or 24V low-voltage DC power to the small battery charging.

Since the DC/DC converter is so important, how do we maintain it on a daily basis?

There are the following precautions.

1. Minimize debris on the heat sink teeth to ensure that the air ducts are smooth when dissipating heat.

2. Ensure that the low-voltage connector is not loose, and ensure that the connector is reliably connected.

3. Check whether the high-voltage connector is reliably connected

4. Check whether there are obvious traces of collision on the shell. And whether there is any damage to the DC/DC converter module.

5. Check whether the positive fuse is loose