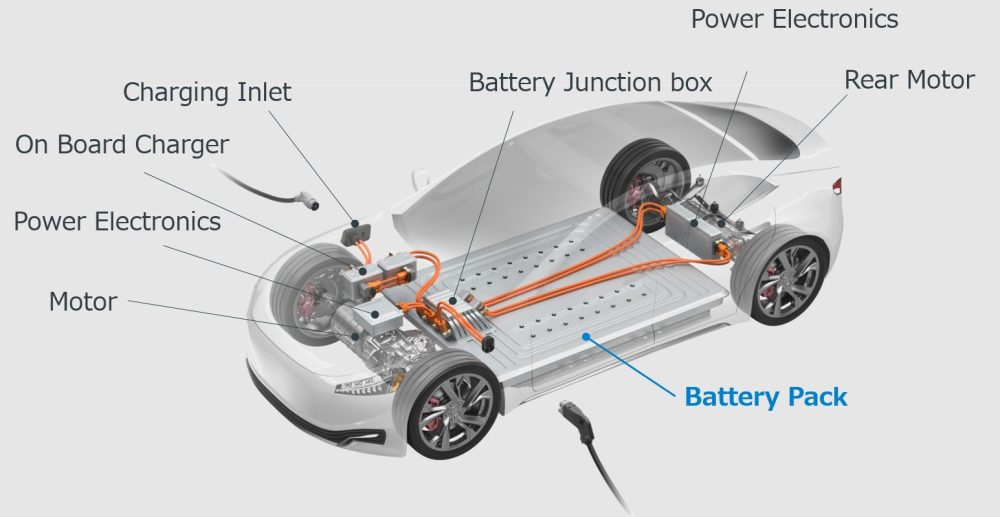

In the autonomous driving systems of new energy vehicles, the Power Distribution Unit (PDU), battery pack, distribution box, and motor controller are core components. The new energy high-voltage signal connectors serve as the crucial link for communication and control between these components. They not only ensure the stable operation of the vehicle’s high-voltage system but also provide essential signal transmission support for autonomous driving functions. Below is a detailed exploration of the role and function of new energy high-voltage signal connectors in autonomous driving.

Core Functions of New Energy High-Voltage Signal Connectors

New energy high-voltage signal connectors are key components in new energy vehicles used for signal transmission, widely applied in the signal transmission between the Battery Management System (BMS), vehicle control unit (ECU), and battery pack. As the core medium for transmission, they are mainly responsible for the following functions:

- High-Voltage Signal Transmission: Through signal connectors, the PDU can monitor the status of the high-voltage system in real time to ensure the safe operation of the battery pack.

- Communication for Battery Management System (BMS): Signal connectors support the communication function of the BMS, transmitting data such as cell voltage and temperature to the central controller.

- Low-Voltage Control Signal Transmission: Communication between the PDU and the low-voltage system also relies on signal connectors to coordinate the cooperation between the high-voltage and low-voltage systems.

Applications and Technical Features of New Energy High-Voltage Signal Connectors

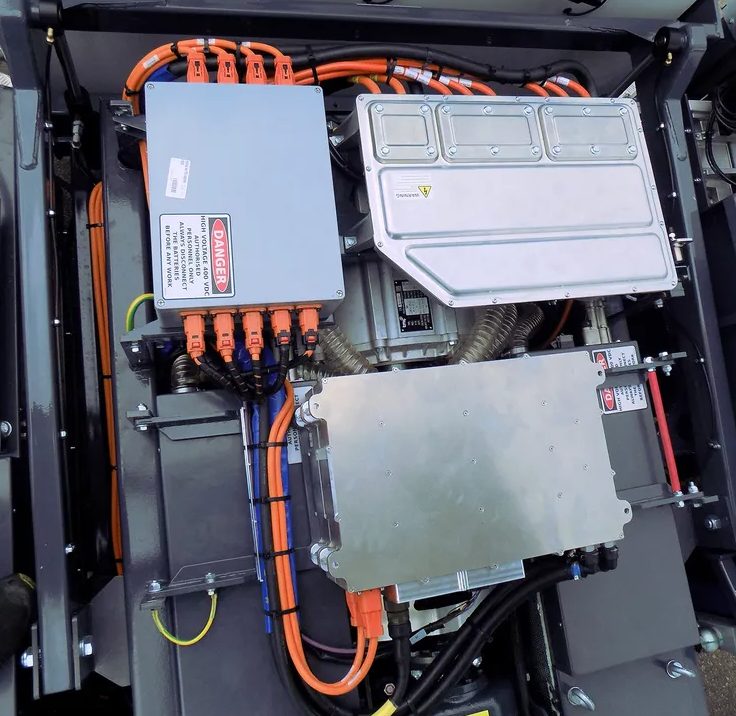

New energy high-voltage signal connectors are commonly used between PDUs, battery packs, distribution boxes, and motor controllers to transmit high-voltage signals ranging from 300 to 1000V DC. For example, the Renhotec FPT series connectors can be used as input and output interfaces for high-voltage signals.

These connectors have the following features:

- Compact Design: Suitable for tight installation spaces.

- High-Pin Support: Available in connectors with 1 to 50 pins.

- Short-Circuit Prevention: Terminal protection design prevents accidental short circuits.

- High Reliability: Made from UL V0 flame-retardant materials to ensure safety.

- Waterproof and Dustproof: Some connectors achieve an IP68 protection rating, suitable for harsh working environments.

Key Roles of New Energy High-Voltage Signal Connectors in Autonomous Driving

Ensuring the Stability of Autonomous Driving Systems

Autonomous driving systems rely on the stable operation of the battery management system. Signal connectors ensure smooth communication between high-voltage and low-voltage systems. For example, through signal connectors, the PDU can monitor the status of the battery pack in real time and quickly cut off the circuit in case of abnormalities.

Supporting High-Bandwidth Communication Needs of Autonomous Driving

With the development of autonomous driving technology, the demand for data transmission within the vehicle is increasing. Signal connectors not only support the transmission of high-voltage signals but also meet the communication needs between the BMS and the central controller.

Enhancing System Safety

The waterproof, dustproof, and short-circuit prevention designs of new energy high-voltage signal connectors, along with the use of high-reliability materials, ensure the stable operation of the battery system in complex environments. For example, connectors with an IP68 protection rating can effectively resist the ingress of dust and water.

Technical Development Trends

1. Miniaturization and Integration: With the development of integrated new energy vehicles, signal connectors will become more compact while offering more integrated functions.

2. High-Frequency and High-Speed Transmission: The increasing demands for data transmission speed and frequency in autonomous driving will drive signal connectors towards high-frequency and high-speed development.

3. Intelligent and Enhanced Reliability: In the future, signal connectors will have higher levels of intelligence, capable of monitoring their own status in real time and automatically switching or alarming in case of failure.

Signal connectors play a crucial role in autonomous driving. They not only ensure the stable operation of the high-voltage system but also support the high-bandwidth communication needs of autonomous driving systems.The quality and stability requirements for automotive connector components are relatively strict.

Renhotec Group places great emphasis on technological investment and has met the corresponding requirements in design and automated production capabilities, achieving mass production of high-end products and providing diversified connector products for downstream vehicle manufacturers.