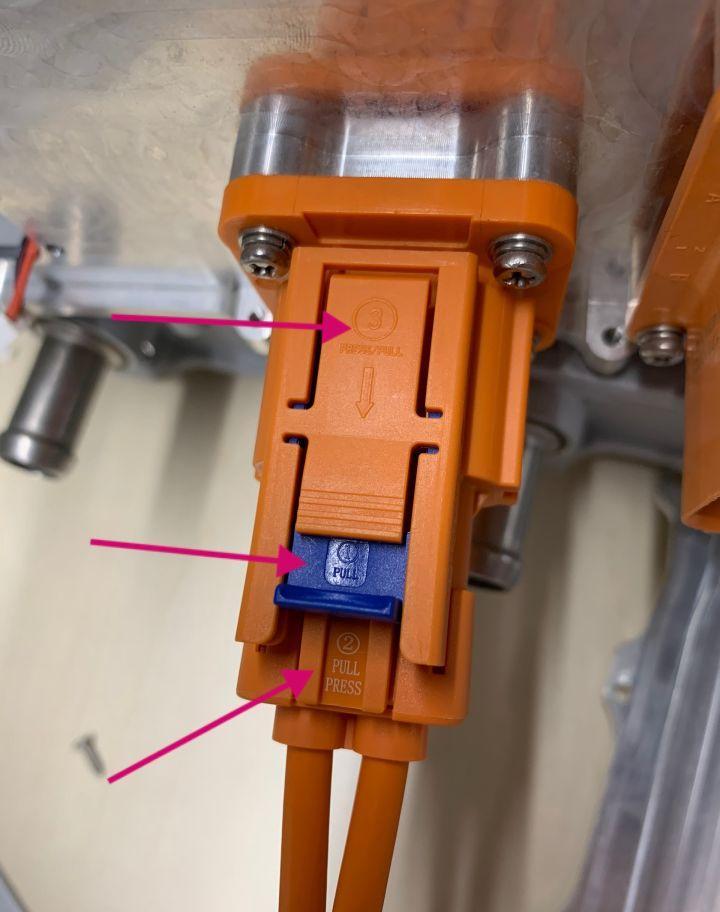

Simply put, high voltage contacts feature a triple lock.

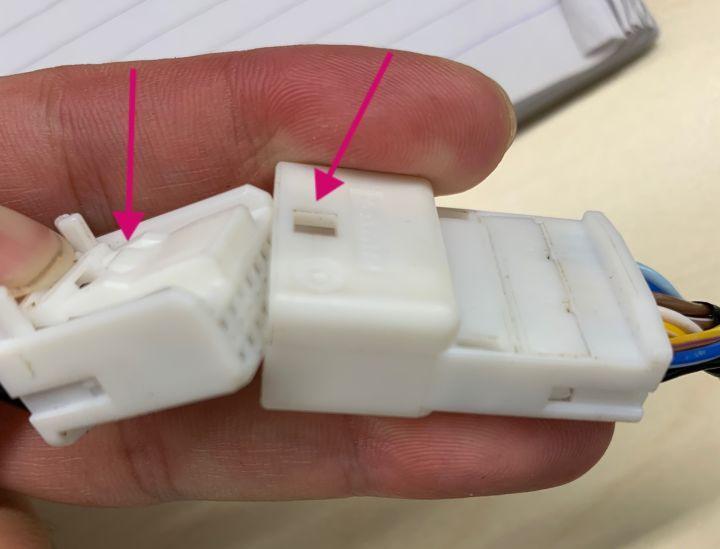

As shown in the figure, 2 is a limit snap that can be pressed down; 3 is also a limit snap that can be pressed down; 1 is also a limit snap. The purpose is to snap the end of 3. In other words, when inserted, first push 3 inward to jam a lock, then continue to make 2 inward, and then jam a lock (hidden inside). At this time, there are already two locks to lock the contact parts.

But for safer insurance purposes, another lock to add. Insert in place, then push 1 inside so that the card is stuck 3. The purpose is to make the end of 3 can not press down to ensure that external forces can not pull out the connector.

Then, when pulling out the connector, one must follow certain steps, according to the order of 1 2 3 to pull out the connector.

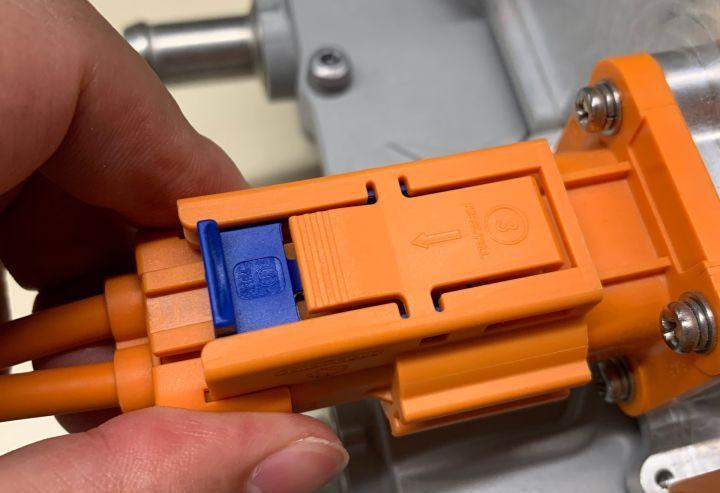

The first step is the 1 out of the card so that the tail of 3 press down.

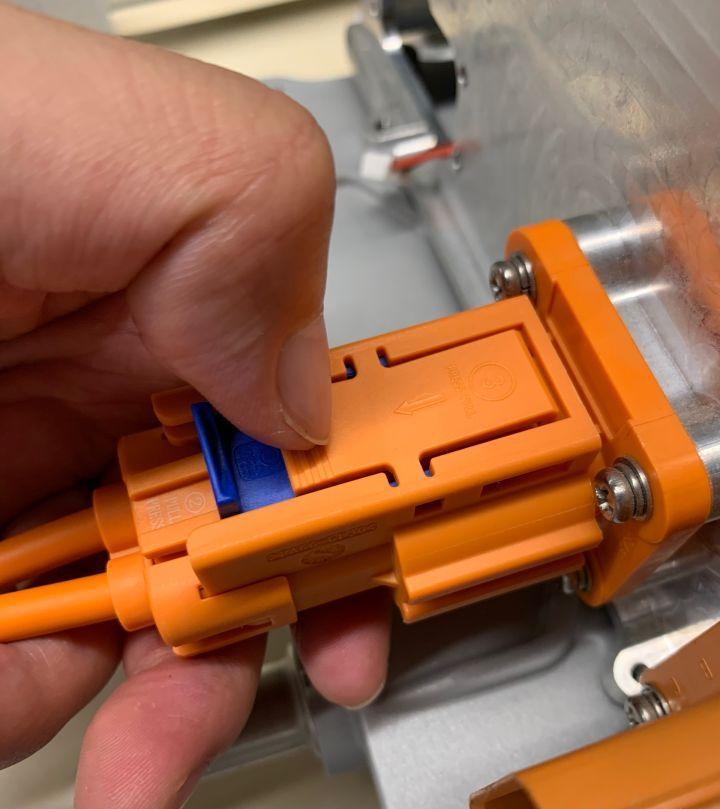

In the second step, press and hold the tail of 2 to pull out. It will be pulled to half of the limit of 3 stuck.

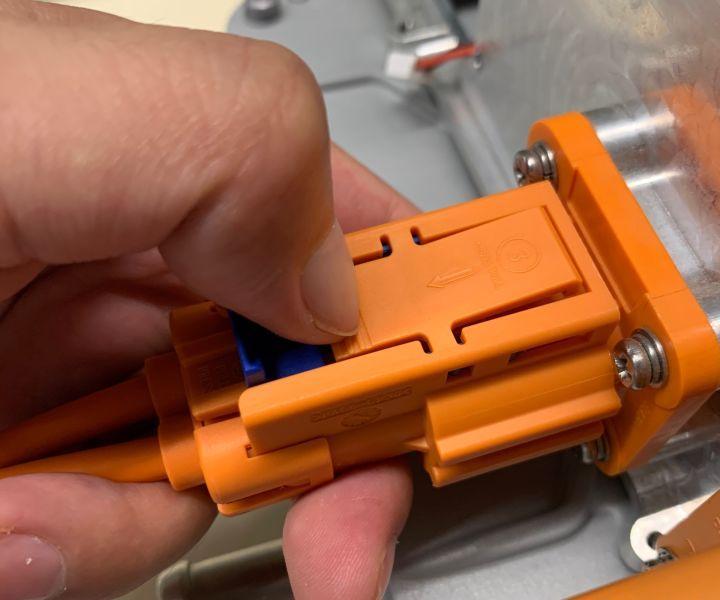

In the third step, press and hold the end of 3 to pull out. Then, you can completely pull out.

Ordinary low voltage connectors have only one lock or layer of snaps.

So, on the electric car, there are some details that ordinary people can not pay attention to in protecting our high voltage safety.

High Voltage Additional Knowledge

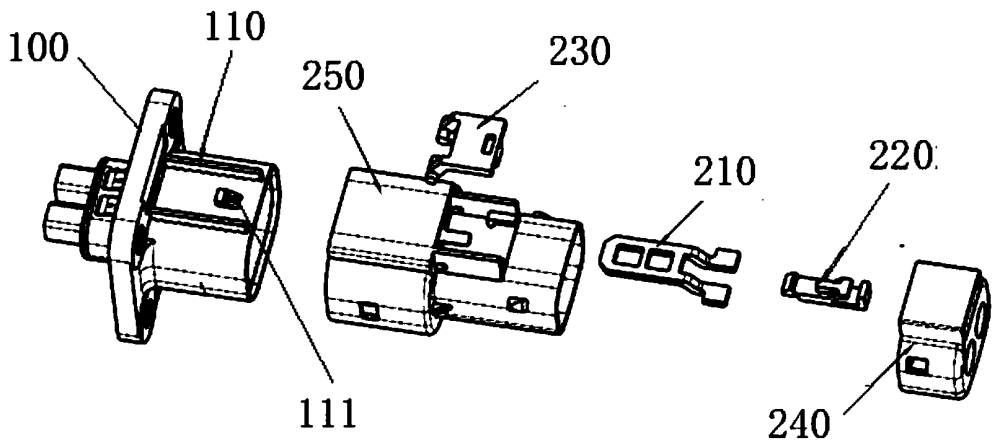

1. Through the information search, the following chart shows the patent of three locks.

Concerning high voltage connectors, there are many other requirements for high voltage connectors are a complete series of technical specifications, which specify, respectively.

First, Technical requirements (including operating temperature, rated voltage, and current, material and surface treatment requirements, structure and design requirements, interchangeability requirements, resistance requirements, contact resistance, insulation resistance, voltage resistance, temperature rise requirements, damp heat cycle requirements, high-temperature aging requirements, temperature shock requirements, temperature storage requirements, salt spray requirements, chemical liquid test requirements, flame retardancy requirements, insertion and removal requirements, mechanical fatigue life, vibration resistance requirements, impact resistance requirements, etc.)

Second, the warranty provisions (including type test, factory inspection, pass the judgment, failure to deal with, etc.)

Third, the test method (including the above types of test methods and standard requirements in detail)

2. High voltage interlocking device for high voltage connectors. A common means of using low voltage to detect and protect against high voltage, but more difficult to control and measure.