Electric forklift battery connectors can come in various shapes, sizes, and colors. This article covers the most common versions and the terminology used to describe them.

These battery connectors are commonly used on electric forklifts and other electric vehicles, such as material handling equipment, ground support vehicles, and golf carts.

The connectors can be broadly classified into 2 categories: flat and Euro-DIN.

Flat Connector

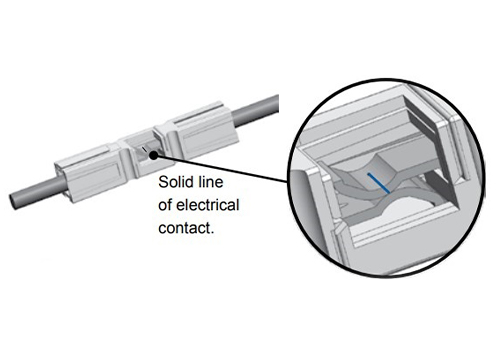

This electric forklift battery connector features “flat wipe technology” contacts. Originally designed by Anderson Power Products, the connector is called the “Anderson Connector.”

The same contact and connector design is used for the battery, charger, and vehicle. Assembly and use are simplified because the connectors and contacts are considered “genderless.”

To connect the 2 connectors, you rotate one connector 180 degrees to connect to the other. This contact type provides a large conductive surface area and has a sacrificial tip that allows for high-current circuit breaks when connecting and disconnecting connectors.

A stainless steel spring holds the mating connector in place, creating pressure and friction between the contacts. The contacts are designed for a life of 10,000 connections.

During assembly, the contacts are typically crimped to the forklift battery cable or, less commonly, soldered to the battery cable.

Forklift Battery Connectors – Color and Voltage

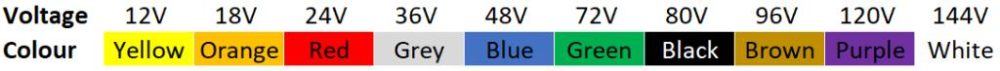

The flat forklift battery connector housings are available in different colors to indicate the voltage and application they are used for. They have a mechanical key molded into the connector housing that prevents accidental pairing of the 2 different colors.

The recommended connector color codes and voltages are:

The flat connectors’ simple design means that there are only 3 primary components:

- Housing

- Main contacts

- Connector Handle

Manufacturers of Flat Connectors

There are several manufacturers of this type of forklift battery connector, the most common being:

- Anderson Power Products (pioneered the design in the 1950s)

- Rema Group GmbH

- SMH (Total Source) Inc

Euro-DIN Connector

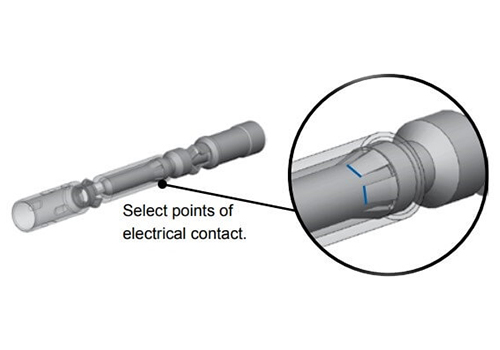

The European-style battery and charger connectors for electric forklift trucks are modular in design and adaptable to the application requirements. This type of connector uses “pin and socket technology,” The contacts are designed to be less susceptible to pitting damage due to plugging and unplugging. The design is based on a female and a male connector.

The male contact pin or female contact socket determines the “gender” of the connector, not the plastic housing. On the battery side, connectors with female sockets are used. On the charger and vehicle side, the connector has a male pin.

During assembly, the contacts are usually crimped to the forklift battery cable. A less common practice is to solder the contacts to the battery cable.

The European DIN standard 43589-1, EN 1175-1, and DINVDE 0623-589 regulate the design and use of such connectors for electric forklift batteries. In principle, connectors from different manufacturers can be mated together.

The connectors follow an agreed innovative keying mechanism, where the key style and position indicate the battery/charger voltage and battery type (wet or dry).

Once paired, positive locking prevents the connector from disengaging due to shock and vibration.

Components of the Euro-Din Forklift Battery Connector

The components that are available for the Euro-DIN battery, charger, and vehicle connectors are:

- Housing

- Voltage pins – usage prevents incorrect connection of given battery voltage to different voltage charger

- Main Contacts, male and female

- Auxiliary contacts, pilot contacts (can provide a data link for forklift battery monitoring and management systems), and reducing bushings

- Air tube adapters for batteries with electrolyte circulation (used during charging to reduce the temperature of the forklift battery).

- Connector handle

- Adapters for water (topping of batteries).

They come in 3 primary sizes, each for a given maximum amperage:

- Euro 80amp

- Euro 160amp

- Euro 320amp

Main Manufacturers of Euro-Din Connectors

The main manufacturers of this type of forklift battery connector are:

- Rema Group GmbH

- Schaltbau GmbH

- Anderson Power Products

- Ravioli

Forklift Battery Connector Inspection and Maintenance

Damage to forklift battery connectors, contacts, and cables can affect their performance, service life, and safety. The following is a list of routine inspections that should be performed at appropriate intervals by battery and connector manufacturer guidelines.

Always check manufacturer and company safety guidelines before beginning maintenance or repair activities. Always stay safe and report problems as they are found.

Euro-Din Molded Connectors – MRC

The Euro-DIN connector’s “molded” version, called MRC, is used on some electric forklifts. These letters stand for molded REMA connectors. The design and current manufacturer of the MRC cable is Rema Group. The design of this connector/cable assembly does not allow it to be repaired. If the connector and cable are damaged, replacing it equally or with a more standard cable assembly is the only viable option.

The advantage of the MRC forklift battery connector is that it is very simple to replace in the event of damage by loosening the harness from the battery.

Dirty Connector Contacts

With Anderson “flat” connectors, the contact surfaces are over-wiped during engagement and disengagement, which helps keep the contact surface area clean. The visual inspection will show if any dirt is present, and if so, wipe the contacts clean. Lubricate the connector with grease suitable for metal-to-metal applications, such as white lithium.

For Euro-DIN type forklift connectors, check for any dirt on the female socket or male pins.

Crimping

Forklift battery connector contacts are crimped to the battery/charging cable as standard. Visually inspect the crimp and check that it is adequate and not loose.

Contact Surface Pitting

If the connector becomes dirty or is frequently disconnected under load, it may cause the contact to show signs of pitting. Once pitting is present, it may cause pitting on other contacts during the mating/disconnecting process. If a dent is found in the contact, it needs to be replaced.

A common cause of pitting is when the battery is disconnected from the charger while the battery is still charging. This can create an arc that dents the contacts.

Connector Shells

We should periodically inspect the connector plastic housing for damage, such as cracks, melting, and discoloration.

Battery Cables

Check the battery and charging cables for signs of damage, including bare copper wires and cracked or broken cables.

Check that the battery and charger handle is secure and show no signs of damage.

Forklift Battery Connector Suppliers

Renhotec has teamed up with the industry’s best suppliers to help you to buy the forklift battery connector you need.

The connector suppliers we are working with our highly knowledgeable and keen to help. If you can’t find the product you need, email us at [email protected].

Rated Forklift Battery connector Products

CONTACT US

Renhotec was established in May 2005 and has been specialized in manufacturing and exporting various electronic connectors for over 15 years.

If you have any needs regarding connectors, please contact us via the phone number or email below

Mobile:(+86)18086610187

Email:[email protected]