Product Type

| Connector Type | |||

|---|---|---|---|

| Orientation | |||

| Number of Positions | |||

| Wire Gauge | 4mm² |

||

| Key | A |

||

| Mounting Type | Cable Mount |

||

| Shell Material | PA66+GF |

||

| Features | Waterproof |

||

| Connector Type | Orientation | ||

| Number of Positions | Wire Gauge | 4mm² |

|

| Key | A |

Mounting Type | Cable Mount |

| Shell Material | PA66+GF |

Features | Waterproof |

Contact Type

| Contact Termination | Crimp |

||

|---|---|---|---|

| Contact Material | Copper Alloy |

||

| Contact Finish | Tin Plating |

||

| Contact Termination | Crimp |

Contact Material | Copper Alloy |

| Contact Finish | Tin Plating |

Electrical Characteristics

| Rated Current | |||

|---|---|---|---|

| Rated Voltage | 800V |

||

| Rated Current | Rated Voltage | 800V |

Environmental Characteristics

| Ingress Protection | IP67 |

||

|---|---|---|---|

| Flammability | UL94 V-0 |

||

| Operating Temperature | -40℃~125℃ |

||

| Ingress Protection | IP67 |

Flammability | UL94 V-0 |

| Operating Temperature | -40℃~125℃ |

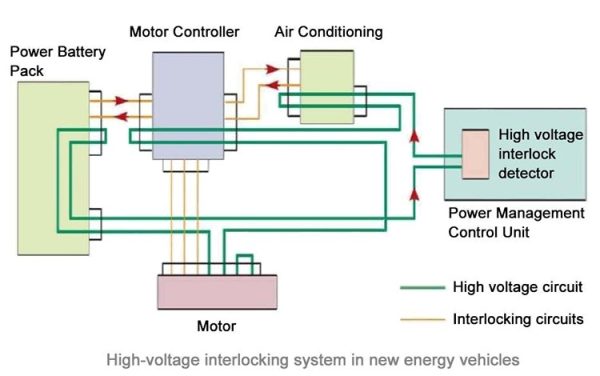

HVIL, or high voltage interlock loop connector, is a safety feature of hybrid and all-electric vehicles that protects people during the assembly, repair, maintenance and operation of a vehicle. The HVIL system is in place to protect those who may come into contact with high-voltage components at any stage of the electric vehicle lifecycle. HVIL acts as a circuit breaker that sends an alert or trouble code to the driver if a high-voltage connection becomes loose, disconnected or damaged during the vehicle’s operation. It also helps protect a vehicle’s driver and passengers in the event of an accident.

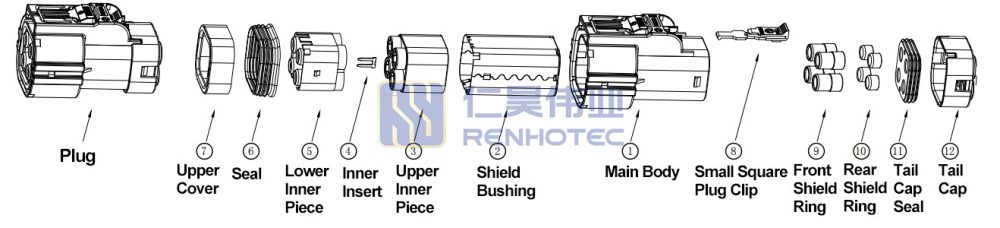

The exact composition of high voltage interlock loop connector plugs may vary depending on the model and manufacturer, but in general, they contain: Housing, Contacts, Pins, Locking Mechanism, Sealing Ring etc.

HVIL connector consists of a plug wrench with a card slot, a secondary lock with a guide slot and a high-voltage interlock microswitch to form an interlock mechanism. High-voltage interlock connectors include solutions for high-voltage, high-current, and signal connections for hybrid and electric vehicle high-voltage power harnesses and signal connections. It is available in a wide range of product options, 1 core to 3 cores, rated from 23A to 250A, touch resistant, single or multi-core shielded cables are available.

Applications

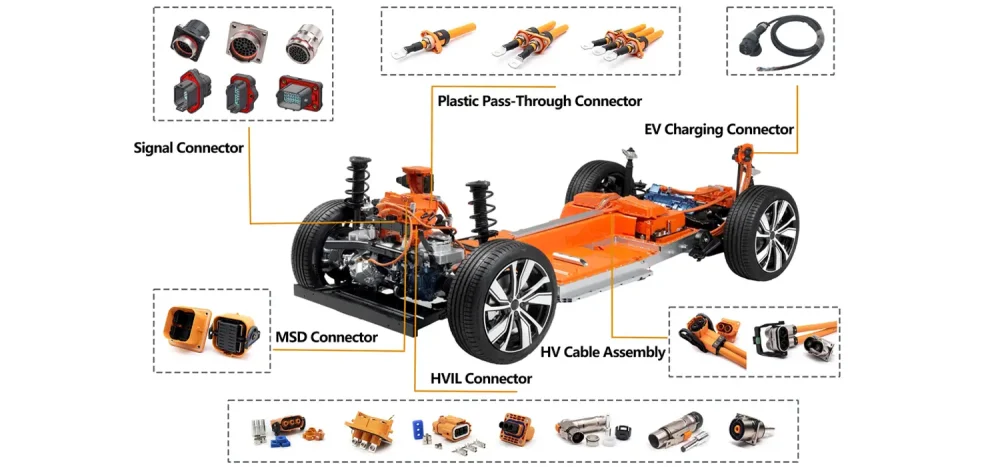

High Voltage Power Distribution, Battery Pack, Motor Controller, Electric Air Conditioning, Electric Heater, etc…

FAQ

The high-voltage connector is an electrical connection component used to transmit high-voltage current and signals, providing 800V-1000V voltage transmission, which is widely used in new energy vehicles, power systems, rail transit, and other fields.

The high-voltage connector is mainly composed of four basic structures: contacts, insulators, housing, and accessories. The contacts are the core for electrical connectivity. The insulator supports the contacts and ensures electrical insulation. The housing is used to protect the entire connector.

There are many types of high-voltage connectors, including unipolar/multipolar, shielded/unshielded, metal/plastic housing, straight/angled, threaded/locking, etc. In addition, depending on the application scenario, there are various models suitable for different voltage levels and current carrying capacity.

Most high voltage connectors, such as Renhotec models, operate within a temperature range of -40 ° C to +125 ° C. However, the specific operating temperature range may vary according to different models and application scenarios.

The high voltage connector must meet electrical performance requirements such as insulation resistance, dielectric loss Angle tangent, discharge current, and voltage resistance test at the rated voltage. During the production process, high voltage connectors are usually subjected to 100% voltage resistance and insulation testing to ensure that there is no risk of poor voltage resistance or insulation during assembly.

Many high-voltage connectors, including Renhotec models, offer IP67, IP68, and IP69K protection ratings. This means they provide excellent dust and water resistance, ensuring reliable performance in harsh environments like rain, dust storms, or high-pressure cleaning.

The service life of high voltage connectors is affected by factors such as material quality, production processes, and operating conditions. In general, high-voltage connectors that have been rigorously tested and verified have high reliability. For example, in mechanical shock and vibration tests, the connector is required to be free of damage, cracking or deformation after completion of the test.

The maintenance of high voltage connectors is very important, mainly including the following aspects:

– Regularly inspect and clean] contact surfaces to remove dirt and oxides.

– Check the fastening of the fixture to ensure the stability of the connector.

– Check the integrity and wear resistance of the insulation material.

– Check the conductivity and heat dissipation of the electrode.

– Periodically test insulation resistance, contact resistance and other performance indicators.

In new energy vehicles, high voltage connectors are mainly used in high voltage control boxes, air conditioning compressors, car chargers, DC-DC converters, PDU, MSD, charging ports, and more. With the high voltage development trend of new energy vehicles, the demand for high voltage connectors is also increasing.

Future trends for high voltage connectors include integration, intelligence, lightweight, and high performance. Examples include smart connectors with sensors for remote monitoring and diagnostics, and connectors using new materials (e.g., advanced composites) and optimized structures to reduce weight while maintaining strength.