Product Type

| Sealing Type | Epoxy Resin |

||

|---|---|---|---|

| Contact Arrangement | 1H(SPST-NO) |

||

| Power Connection | Stud Terminals |

||

| Coil Connection | Flying Leads |

||

| Sealing Type | Epoxy Resin |

Contact Arrangement | 1H(SPST-NO) |

| Power Connection | Stud Terminals |

Coil Connection | Flying Leads |

Contact Type

| Contact Material | Silver-plated Copper |

|---|---|

| Contact Material | Silver-plated Copper |

Electrical Characteristics

| Rated Current | |||

|---|---|---|---|

| Rated Voltage | 12-1000V |

||

| Rated Power | 1.7W |

||

| Coil Voltage | 9-36V DC |

||

| Contact Resistance | ≤0.2MΩ(6V DC/20A) |

||

| Max. Switch Current | 2000A(320V DC) |

||

| Operating Voltage | 8V-9V DC |

||

| Release Voltage | 6V-7V DC |

||

| Rated Current | Rated Voltage | 12-1000V |

|

| Rated Power | 1.7W |

Coil Voltage | 9-36V DC |

| Contact Resistance | ≤0.2MΩ(6V DC/20A) |

Max. Switch Current | 2000A(320V DC) |

| Operating Voltage | 8V-9V DC |

Release Voltage | 6V-7V DC |

Environmental Characteristics

| Operating Temperature | -40℃~85℃ |

|---|---|

| Operating Temperature | -40℃~85℃ |

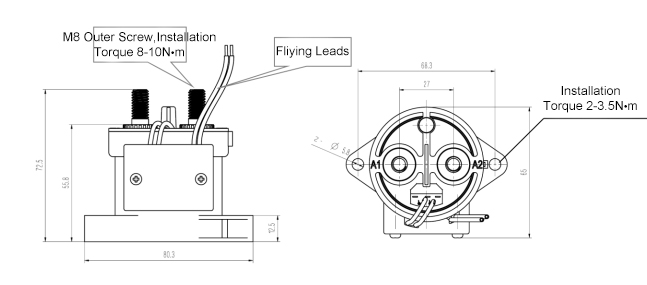

High Voltage DC Contactor

The contacts of high-voltage DC contactors are designed to handle the high current levels of the system without overheating or arcing. They are typically spring-loaded to ensure that they remain in contact during operation and have a large surface area to ensure a low resistance path for the current. The contacts are also designed to be easily replaceable in the event of damage or wear.

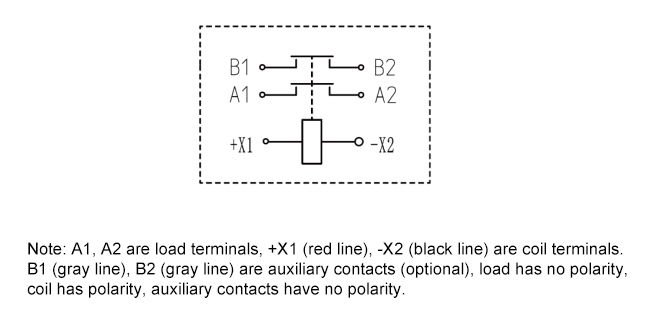

High Voltage DC Contactor – Wiring Diagram

The wiring diagram of the high-voltage DC contactor can be described as follows. The wiring diagram includes the input and output terminals.

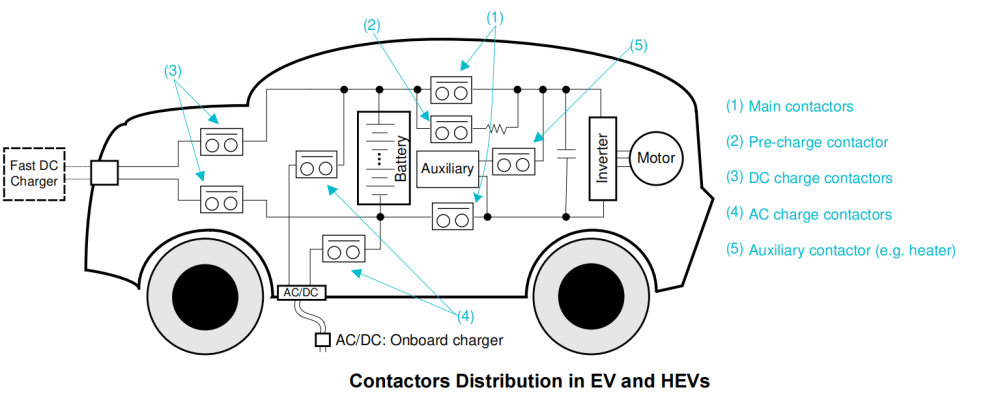

Applications

Featuring a magnetic arc blowout design and IP67 sealed, gas-filled chamber. Renhotec High Voltage DC Contactor Relay was developed for the below applications:

Battery Electric Vehicles (BEV)

Hybrid Electric Vehicles (HEV)

DC Charging Station

Energy Storage System