Product Type

| Series | SQD Series |

||

|---|---|---|---|

| Connector Type | |||

| Orientation | |||

| Shell Material | Stainless Steel, Aluminum alloy |

||

| Spring | Corrosion Resistant Stainless Steel |

||

| Sealing Type | Bidirectional Dry Break Seal for No Dripping, Various Chemically Compatible Rubbers Available |

||

| Diameter | 4mm, 5mm, 10mm |

||

| Series | SQD Series |

Connector Type | |

| Orientation | Shell Material | Stainless Steel, Aluminum alloy |

|

| Spring | Corrosion Resistant Stainless Steel |

Sealing Type | Bidirectional Dry Break Seal for No Dripping, Various Chemically Compatible Rubbers Available |

| Diameter | 4mm, 5mm, 10mm |

Electrical Characteristics

| Work Pressure | 0.3-1MPa |

|---|---|

| Work Pressure | 0.3-1MPa |

Mechanical Characteristics

| Mating Cycles | ≥1000 |

|---|---|

| Mating Cycles | ≥1000 |

Environmental Characteristics

| Operating Temperature | -40 °C to 105 °C (or -55 °C ~ 150 °C) Seal Material Determined |

|---|---|

| Operating Temperature | -40 °C to 105 °C (or -55 °C ~ 150 °C) Seal Material Determined |

Why Liquid Cooling

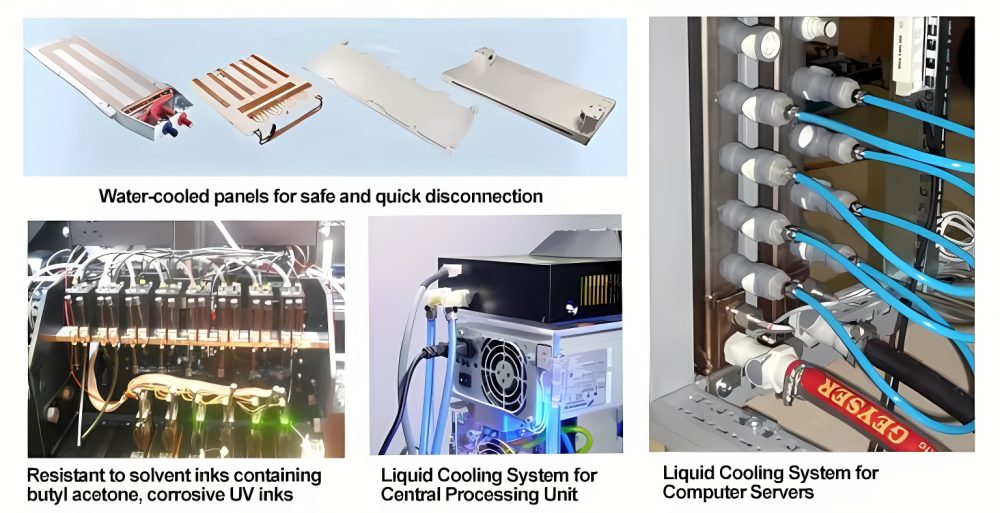

As electronic systems become more complex and operate at higher power, dissipating excess heat efficiently becomes one of the biggest issues. With customers demanding lower weight, smaller sizes and solutions in a range of costs, liquid cooling is the answer. Thermal management with reliable liquid cooling quick disconnects fittings is required to help prevent failures and improve system efficiency.

The increase in demand for efficient thermal management in industries such as computing, data centers, electric vehicle (EV) fast charging, telecom, lasers and medical equipment is leading to the growth of liquid cooling. With liquid having the capacity to transfer heat faster and more efficiently than air of the same mass, what liquid is used for liquid cooling matters less than the fact that it works. Renhotec’s connectors as part of a liquid cooling solution will help you cool higher loads — and do it more effectively.

Reliable, High-Efficiency Liquid Cooling Quick Release Connectors

With the increased use of liquid cooling for thermal management, thermal engineers demand high-performance quick disconnect solutions to help keep the systems they design reliably cool while also enabling hot swapping and ease of maintenance.

Renhotec’s thermal management experts understand the complexities of performance and the system environments where liquid cooling connectors are used. The result of this expertise and experience is Renhotec’s reliable and robust Renhotec liquid cooling quick disconnects (QDs), which are compatible with a wide variety of coolants. They are available in a variety of materials, sizes and configurations to meet different system requirements.

Renhotec liquid cooling connectors are ideally suited for most liquid cooling environments ─ anywhere hot electronics need efficient cooling. Trusted by manufacturers worldwide, Renhotec liquid cooling quick disconnects help keep electronics cool, which can increase operating efficiency and improve system performance.