Electric vehicles have high voltage above 600 V and high current system above 300 A. The connector system of high-voltage circuits, especially the internal contact structure of high-voltage connectors, play a vital role in ensuring the safety of the high-voltage circuit.

The conventional automotive connector contact structure cannot meet the standard requirements in electrical safety and contact resistance.

The high-voltage petal contact structure applied in the power industry is simple to process but has few contact points, high contact resistance, and difficulty controlling processing accuracy.

Many electric vehicle high-voltage connections researchers recently continued to design new internal contact structures for high-voltage connectors.

We have done a lot of research work in this area.

- Elastic Jack Contacts

- Porous Wear-resistant Structure

- Elastic Jack Contacts

- Contact Type Elastic Internal Contact Structure

- Leaf-spring Contact Structure

- A New Type of Cylindrical Crown Spring

- Elastic High-voltage Plugs

Double Helix and Wire Spring Contact Structure

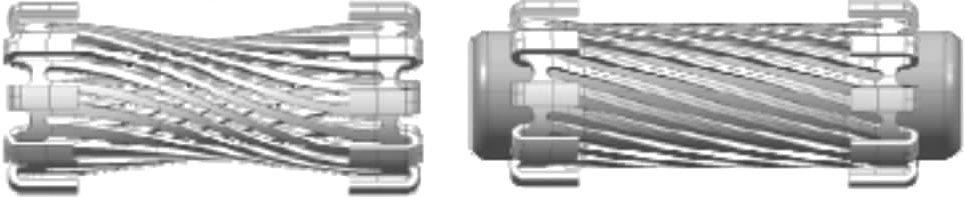

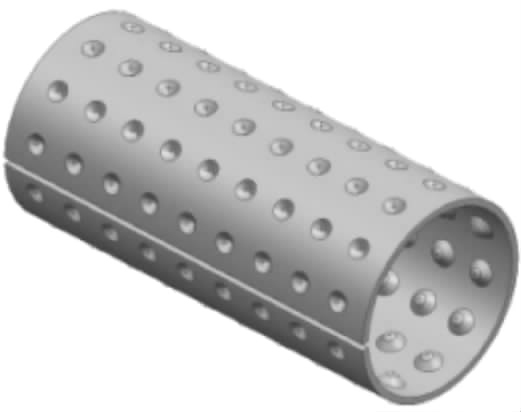

Amphenol‘s contact structure solution for high-current connectors in motor control and motor drive in electric and hybrid vehicles is a double helix structure (Figure 1).

Features:

- This structure has a contact area of 65% and offers low insertion/removal forces and high reliability.

- It has a relatively high overload capacity with an operating voltage of up to 630 V and a rated current of 455 A.

Advantages:

- With a mechanical life of more than 500 cycles, it is one of the famous internal contact structures in the field of high-voltage connections for electric vehicles.

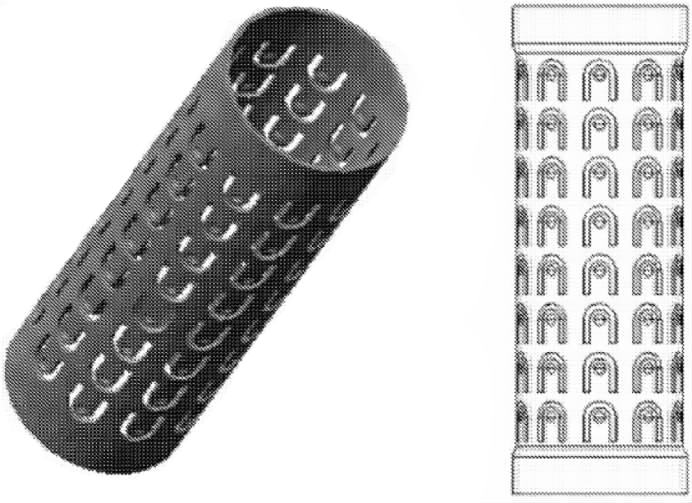

Rosenberger’s wire spring contact system (Figure 2) is capable of more than 40 contact points, high current carrying capacity, space-saving, low contact resistance and plugging force.

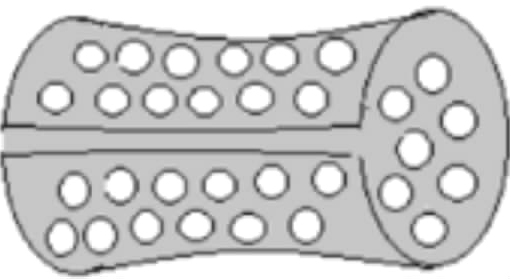

Porous Wear-resistant Structure

We developed a porous wear-resistant inner contact ring for electric vehicle high-voltage connectors, including a porous elastic inner contact ring (Figure 3) and a surface coating.

Feature:

- The porous elastic contact ring is a highly elastic copper-nickel-silicon alloy open tube with a wall thickness of 0.5 mm, an inner diameter of 8 mm, and a length of 19 mm.

- The tube is curved and concave in the middle, with an inner diameter of 5 mm and holes of 1.5 mm in diameter distributed on the wall.

- The tube has a line slit along the axis, and the width of the slit is controlled within 0.5 mm.

- The surface coating is one of AgCu, AgSb, AgPd and AuAg alloys with a thickness of 0.5~2.0 μs.

Advantages:

- The contact has a simple structure, reliable performance, and many applications.

This porous wear-resistant elastic inner contact ring achieves a reticulated linear contact with the plug with low contact resistance, meeting the contact resistance requirements of LV215 high-voltage connectors.

AgCu, AgSb, AgPd and AuAg alloy coatings are used instead of pure Ag or pure Au coatings for the inner contact ring to improve the wear resistance of the inner contact structure.

When the content of Pd in the alloy coating is 8%~10%, the wear resistance is 5~10 times higher than that of pure silver. 30%~40% of Ag in the AuAg alloy coating increases the wear resistance 8~10 times higher than pure gold.

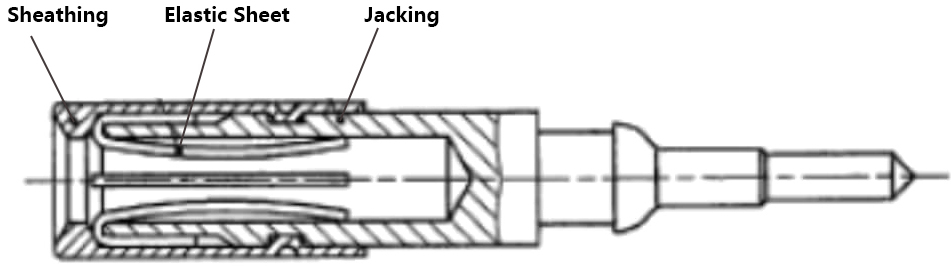

Elastic Jack Contacts

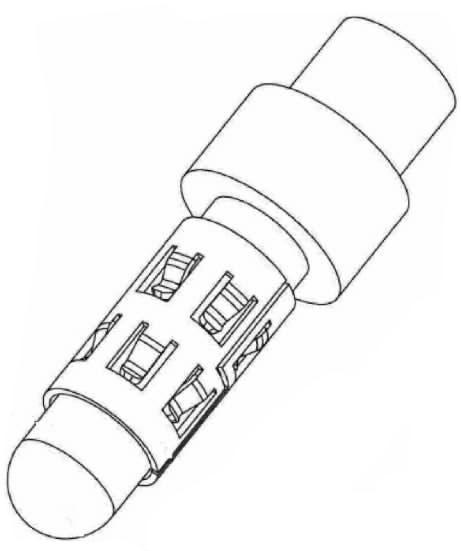

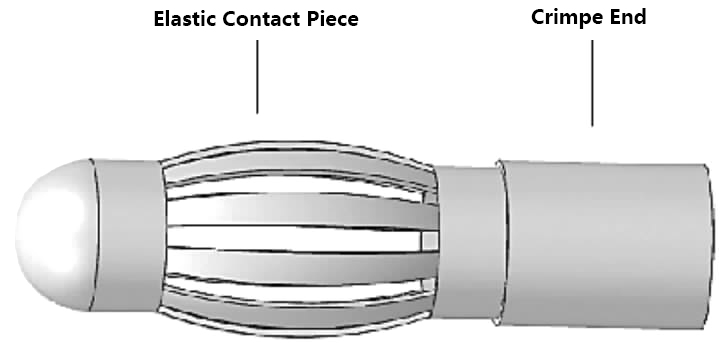

Shibin Zhao designed an elastic jack contact (Figure 4) consisting of a sheath, an elastic member and a jack.

Feature:

- The elastic contact parts are made of elastic wire or elastic strip and are evenly arranged around the circumference of the jack.

- The circular contact part is suspended toward the centre of the jack to form a sliding pivot point, and an inner contact jack is formed in the radial direction of the jack.

Advantages:

- The structure has the advantages of simple structure, low insertion and extraction force and high load capacity.

Contact Type Elastic Internal Contact Structure

We have recently developed a contact type elastic internal contact structure, including an elastic contact ring (Figure 5), a cylindrical contact head and a socket body.

Feature:

- The resilient contact ring is fixed in the socket body and then docked with the cylindrical contact head.

- The elastic contact ring is an open tube structure with curved bumps uniformly distributed on the inner side.

- The diameter of the open tube of the elastic contact ring is 3~16 mm, the radius of the arc-shaped bump is 0.5~1 mm, and the height of the arc-shaped bump is 0.2~0.5 mm.

Advantages:

- The structure is simple to process, and reliable in performance, and the multi-contact elastic contact structure has low contact resistance.

- It can meet the contact resistance requirements of LV215 high-voltage connectors.

Jibing Feng set multiple arrays of bumps on the laser skeletonized connection tube (Figure 6) to obtain the multi-contact positive pressure stably and ensure contact reliability.

Leaf-spring Contact Structure

Yi-Ping Peng invented a leaf-spring contact structure (Figure 7).

Feature:

- The structure includes a C-shaped or ring-shaped body and several reeds, which have contact tabs facing the axis of the body.

- This structure has better elasticity and resistance to plugging and unplugging.

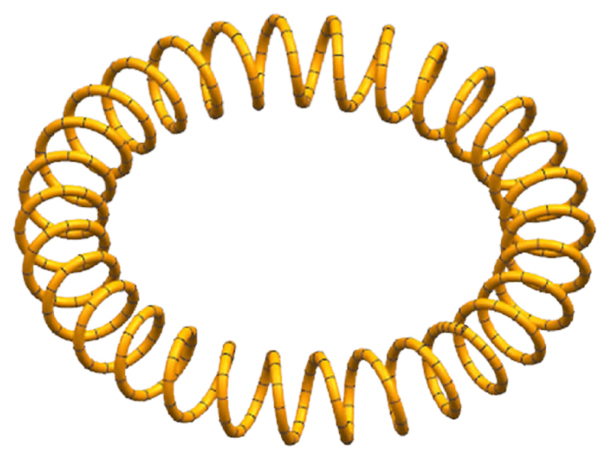

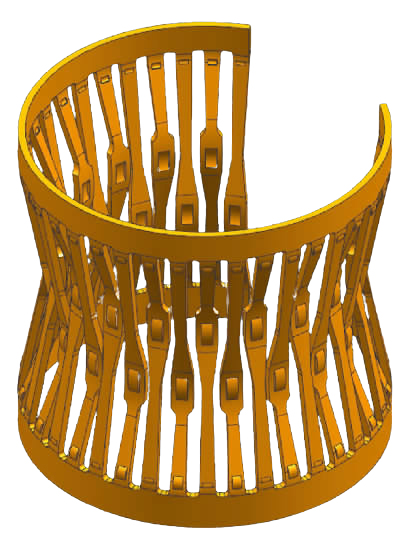

A New Type of Cylindrical Crown Spring

Recently, our team has designed a new type of cylindrical crown spring (Figure 8).

Features:

- This structure consists of two band rings and several reeds set between the two band rings.

- Each reed has a contact portion extending axially toward the cylindrical crown spring.

Advantages:

- This structure has more contact points and can effectively reduce contact resistance.

- The reeds have multiple layers of bumps inward, which can contact the pins in layers during pin insertion and effectively reduce the pin insertion/removal forces.

Elastic High-voltage Plugs

All the above contact structures are contacted through intermediates, not direct contact between plug and socket. We have developed a resilient high-voltage plug (Figure 9) with a linear resilient contact piece that directly contacts the socket.

Features:

- Instead of conventional silver or gold plating, silver-nickel, silver-nickel nano-graphite flake, or silver-nickel carbon nanotube composite plating is used to improve the hardness and wear resistance of the plating.

- Based on the high-voltage petal socket, the plug surface is made into a tooth thread, which also achieves linear contact between the plug and socket to ensure the reliability of the high-voltage connector contact based on no medium body.

Conclusion

In summary, there are two trends in the structural design of high-voltage connectors.

One is to change from the original low-voltage surface contact to high-voltage under the double helix curve structure, wire spring structure, porous wear-resistant structure, leaf spring contact structure, elastic jack structure of wire contact to increase the contact area, reduce contact resistance and improve the current-carrying capacity.

The other uses a multi-contact contact ring, a skeletonized connection tube with an array of bumps, and the new cylindrical crown spring to achieve direct point contact to reduce contact resistance and improve the current-carrying capacity. The flexible high-voltage plug can form direct linear contact with the socket, without intermediaries such as crown springs.