The two years of renovation, know that you have to buy thicker and thicker wire with more and more appliances at home. The same problem exists for automotive high voltage harness. Household electrical wire is generally a single-stranded copper core wire, thickness in square millimeters (mm²), “4 flat” is the cross-sectional area of 4mm².

Physics tells us that W=I²Rt.

At the same temperature, each wire’s corresponding current carrying capacity is constant. Wire resistance is inversely proportional to the cross-sectional area. The thicker the wire, the lower the resistivity, and the less heat generated by the same current. Once the actual current exceeds the maximum current allowed by the wire, it will cause the wire to overheat and even burn.

This means that the thicker the wire, the greater the number of “flats” that can withstand greater current, the same voltage to withstand greater power. The voltage of home electricity is 220V, according to the rated current and rated power of electrical appliances, to select the most suitable wire.

Reasonable Power of Wires in Domestic Circuits

| Cross-sectional Area of Conductors | Suggested Current | Recommended Power | Recommended Appliance |

|---|---|---|---|

| 1.5mm² | 10A | 2200W | Lighting line |

| 2.5mm² | 16A | 3500W | Common socket |

| 4mm² | 25A | 4800W | High power appliances |

| 6mm² | 36A | 6000W | Central air conditioning, incoming bus |

| 10mm² | 50A | 8500W | Intake bus |

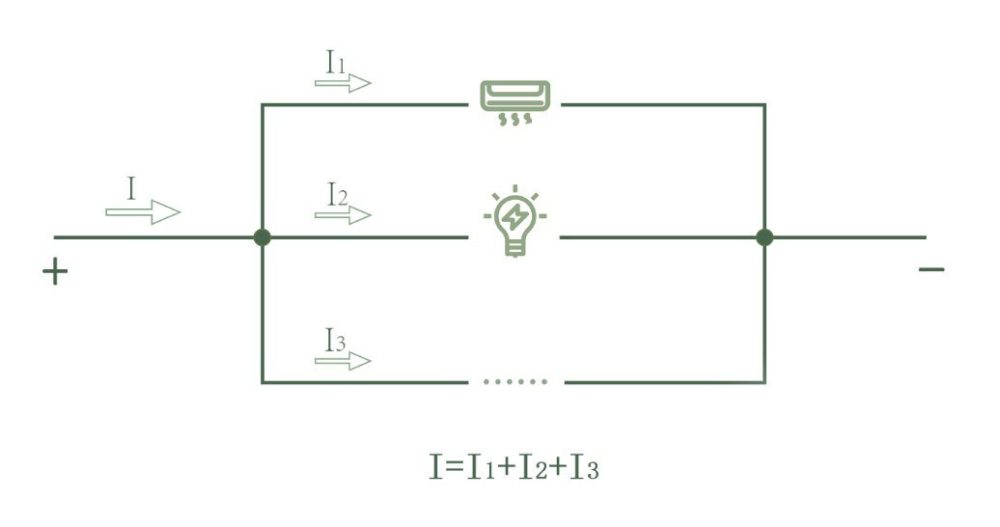

How do you calculate the current of more than one appliance in the room, the air conditioner, and the water heater? Household appliances are in parallel. Add up the current of several appliances and compare it with the recommended current of the wire.

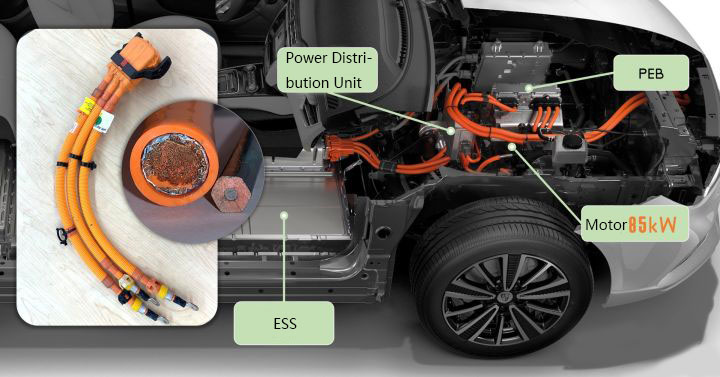

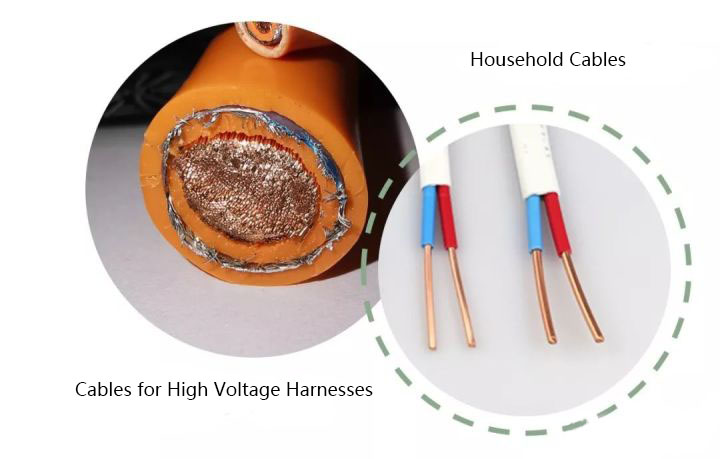

The above principle applies to other electricity-using situations, such as new energy vehicles. The two high-voltage wires of the two cars were put together and photographed. According to the above conclusion, the thicker the wire with solid material, the more available power.

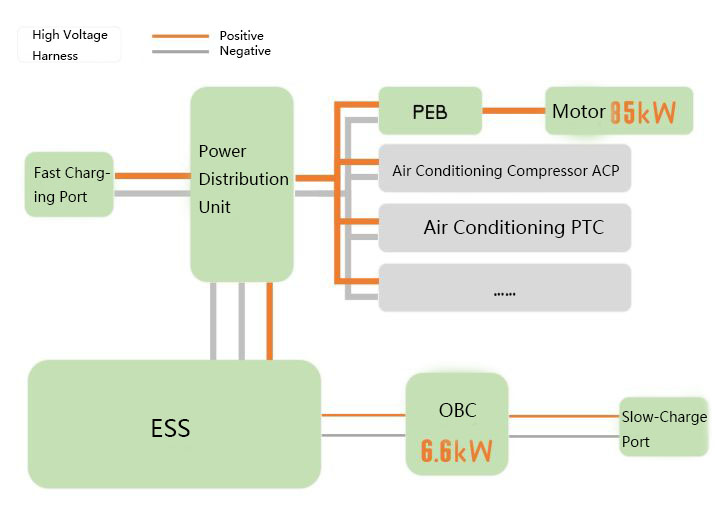

There is not just one high voltage wire harness used in new energy vehicles. There are 3mm², 4mm², 16mm², 25mm², 35mm², 50mm² and even 70mm² and many more. For example, in the case of the Rongwei Ei5, the high-voltage wire used for the 85kW motor is different from the high-voltage wire used for the 6.6kW charger at nearly 400V. The “thickness” is the difference in the cross-sectional area of the copper wire, which is also evident.

The specific location distribution on the car can be represented by the following diagram.

So, both are necessary high-voltage wiring harnesses for new energy vehicles, just assembled in different locations according to the power requirements. So if the car is thicker, the wire can not be used? Isn’t this safer?

- There is strict management of the weight and space of the parts on the car.

- The thicker the wire, the more expensive it is. There is no need for this.

- A thicker wiring harness will have a larger turning radius.

The Special Design of High Voltage Harness for Vehicles

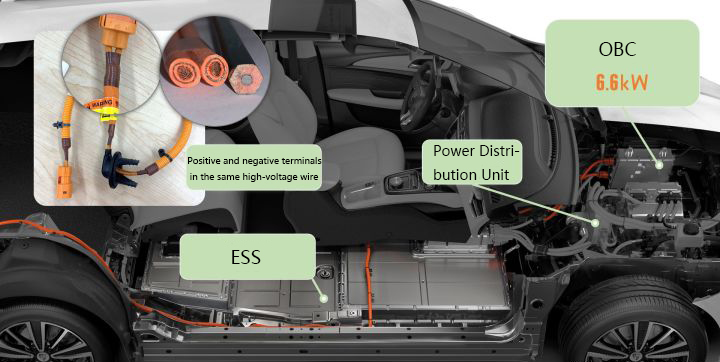

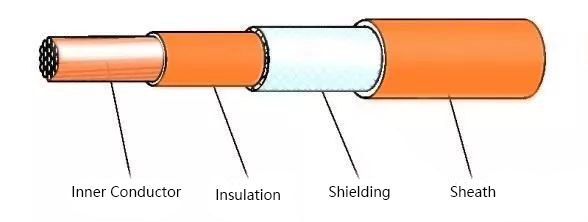

1. Household cable for a solid copper core, while the car’s high-voltage cable is most likely composed of multiple thin copper wires.

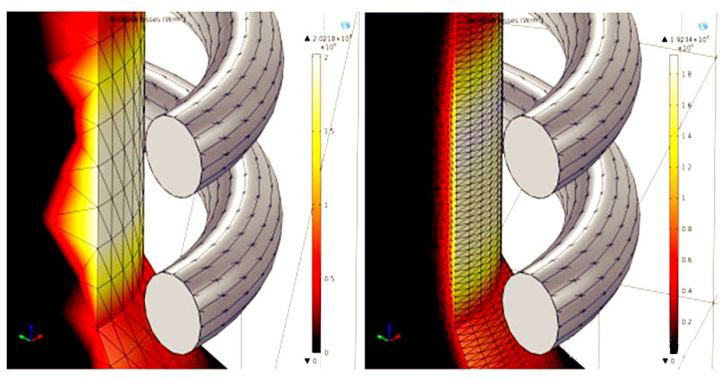

The reason for this is to increase the conductivity. When the conductor has an alternating current or alternating magnetic field, there will be a “skin effect” the current will be concentrated in the wire’s “skin part “. And the current density on the surface of the conductor is greater than the density of the center. Roughly speaking, it can be understood that the main conductor conducts electricity by the surface.

And the higher the frequency of the alternating current, the more obvious the “skin effect” will be. The high voltage platform of a new energy vehicle is 300-400V, and the frequency can reach kHz level, which is tens of times higher than that of a household appliance, so the high voltage wiring harness must have a reduced “core” area.

And there are other benefits. The main high voltage harness has a cross-sectional area of 50mm², which is 5-10 times thicker than a household appliance. It is much more rigid and difficult to bend. It is difficult to lay out in a car, but it can also pierce into the cockpit after a collision, increasing the safety risk. Considering strength and toughness and safety, multi-core wire is also a better choice.

2. Vehicle High Voltage Wiring Harness with Shielding Layer

Maxwell said that electricity generates magnetism. When a current passes through a wire, a magnetic field is built around it. The shield shields this electromagnetic field within the wire harness. It does not affect other components while reducing electromagnetic radiation. It also shields against external influences and prevents interference from outside magnetic fields.

The basic principle of home and car wiring harness is the same. According to the current and voltage, both need to choose the correct wire, not necessarily the thicker, the better. Moreover, due to the more demanding conditions of use, the standards of automotive high-voltage harnesses are more demanding. The design will also consider more details for safety and durability.